Testing heat pump systems for space heating, space cooling and domestic hot water preparation is a complex task, especially when several energy sources and storage options should be taken into account. The measurement of individual steady-state operating conditions can hardly represent all relevant operating conditions. Moreover, the influence of the control strategy in dynamic operation is of decisive importance. For this reason, measurements using the hardware-in-the-loop approach are performed in the TRI-HP project to test the performance of the newly developed systems.

The experimental setup took place in the laboratories of IREC in October 2021, where the dual source system have been tested, and SPF-OST, where the solar ice system have been tested. The principle of the tests are described, as well as the hydraulic and electrical schematics required to be mounted to complete such tests. Furthermore, as it is not possible to run the experiments for a whole year, a methodology has to be implemented to select the days that are more representative of a yearly operation. Only these particular days of the chosen climates have been tested in the labs, and the results extrapolated for obtaining an annual balance. The Concise Cycle Test (CCT) method was applied in this case, using data of the climate, loads and ice storage status to group them into clusters and choose the most representative days of these clusters. The resulting chosen periods are presented in detail in our extended report.

Simulation process using Concise Cycle Test (CCT) method

The method used in TRI-HP is the Concise Cycle Test (CCT) and this is applied in the laboratories of SPF as well as IREC, each in a version adapted to the systems to be tested. The common feature of the measurements is the systematic approach with the emulation of the fluctuating sources and sinks. The procedure for simulation and emulation can be described as follows: a real-time online simulation runs in parallel to the measurement. At the end of each simulation/emulation time step, measured values are passed from the test bench control software to the system simulation software. Based on these values, the simulation software is simulating the answer (response) of the emulated device for the next time step and returns the result to the test bench control software. During the next time step, the test bench control software controls the emulation of the simulated device, while the simulation software pauses and waits for the next input of measured values from the test bench control software.

Selection of test cycle periods

Two different systems have been tested in the CCT:

i) the solar ice-slurry system including a propane or CO2 heat pump with an ice-slurry storage and solar thermal collectors, designed for the climatic conditions from central Europe with heating as the main purpose and only low cooling demands. The system efficiency is strongly dependent on the status of the ice storage, therefore a selection based on weather data is not sufficient. Annual simulations of the whole system were used to get a database for the selection of days considering the weather conditions, the heating demand and the status of the ice-slurry storage.

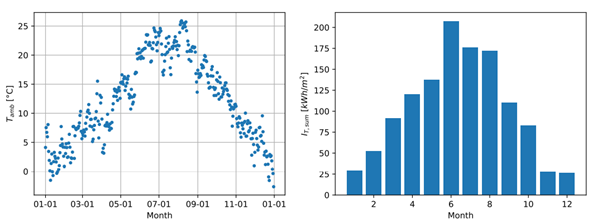

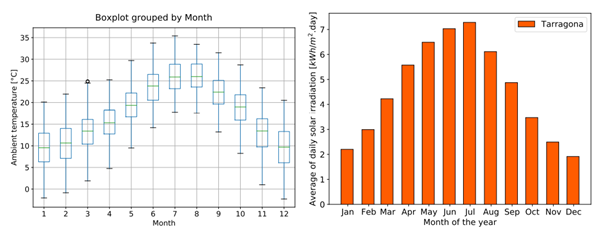

ii) the dual source system including a reversible propane heat pump with air and/or ground as source, is designed for the climatic conditions from southern Europe with higher cooling demands. The source temperatures, and therefore the system efficiency, mainly depend on the weather conditions, therefore the days for the test cycles are chosen from the weather conditions in combination with the thermal demands of the building (from building simulation).

For the ice-slurry system, 7 individual days from the entire year were combined into a continuous test cycle with contiguous days from different seasons. In this way, the ice-slurry storage scaled to laboratory scale can also be included in the test. For the dual source system, series of 4 consecutive days were gathered into clusters depending on weather conditions, and one series of 4 days was selected as representative for each cluster. These selected series of 4 consecutive days are tested individually. In this way, the smart control strategy can also be tested on a longer period, to assess its benefits and observe its behaviour from one day to the next in terms of storage strategy. Key Performance Indicators were defined to verify the intended goals from the system developments.